Industrial endoscope is a kind of non-destructive testing equipment widely used in the field of industrial manufacturing and maintenance. It extends the visual distance of the human eye, breaks through the blind angle of human eye observation, and can accurately and clearly observe the internal surface of machinery and equipment or parts. Conditions such as wear and tear, surface cracks, burrs and abnormal attachments, etc., avoid unnecessary equipment decomposition, disassembly and possible component damage during the inspection process. It has the advantages of convenient operation, high inspection efficiency, and objective and accurate results. , Is a powerful tool for enterprise production process control and quality control.

The industrial optical hard tube video endoscope is a new type of diagnostic instrument that uses the combination of optics and optical fiber technology, precision machinery and electronic technology. Widely used in the inspection and maintenance of deep holes, blind holes, cross holes and internal surface quality in small spaces in the manufacturing process of rolling stock, automobiles, machinery, hydraulic devices, petrochemical, machinery, aviation, weapons, transportation, railways and other sectors. In-process internal surface quality inspection. The optional video display system combines the imported high-definition camera system CMOS with the eyepiece.

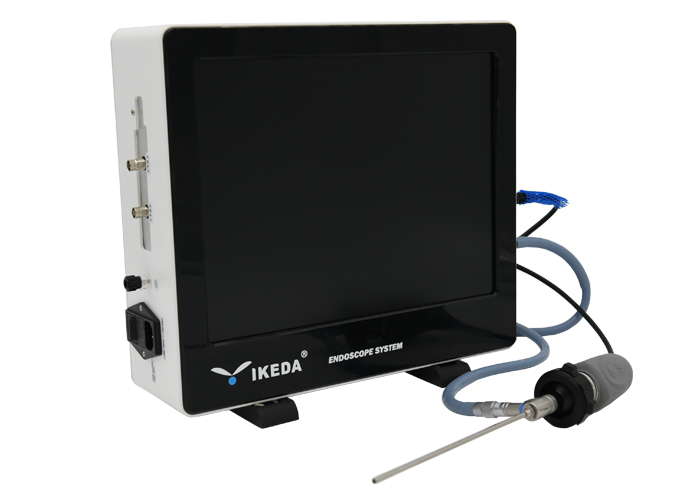

The image is displayed through the industrial monitor to show the wear and tear, surface cracks, burrs and abnormal attachments of the inner cavity of the inspected object, which is more convenient for the observation of the inspected part. You can also connect an external handheld video recorder to record and store images. And it can be connected with the computer to perform operations such as freezing, playback, processing, and archiving of pictures.