Cars have become inseparable from the lives of modern people. Among the various parts of the automobile, castings are an important part of the automobile. From the automobile chassis to the engine, structural parts, and security parts, all are closely related to the production of die-casting technology. Automobile castings include very important engine blocks and cylinder heads, and the casting molding process has huge advantages.

However, due to differences in processes and materials, temperature, gas, water vapor, environment or other factors in the production process may cause various defects in castings, such as shrinkage, shrinkage, porosity, cracks, pores, sand holes, slag inclusions And so on, these defects may have an adverse effect on the product, thereby affecting the service life.

In the process of quality inspection of automobile castings, it is necessary to observe the internal conditions of some small holes, or possible defects in the internal cavity of the casting, especially the internal curved channels. The general method is more difficult to achieve.

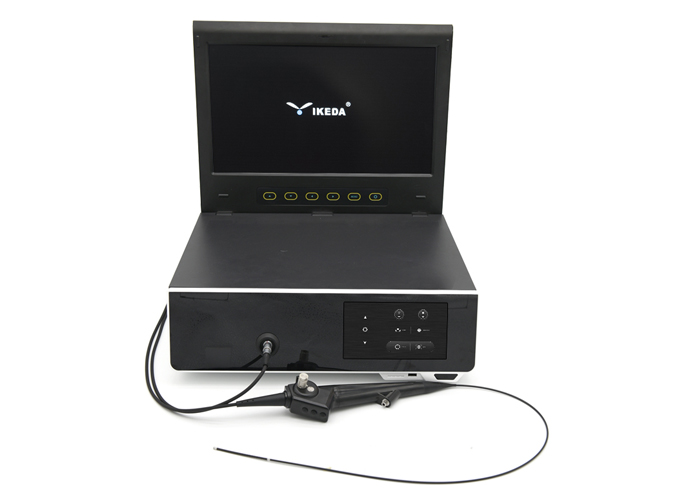

The industrial endoscope is an electronic video endoscope, which uses a miniature image sensor for photoelectric conversion, which is more reliable and has a longer service life. Industrial endoscopes can be used to detect defects on the inner surface of castings. As a visual non-destructive inspection tool, it is characterized by intuitive visibility, clear images, all-round steering, lightness and portability, and can effectively extend the viewing distance of people and observe the eye. Out of reach. It is widely used in the production and manufacturing of auto parts, such as internal inspection of exhaust pipes and internal defect detection of various castings. It effectively plays an active role in the process of automobile assembly and after-sales maintenance and reduces the workload of relevant personnel.